3D Printing Solves Supply Chain Challenges

3D Printing: The Future of Supply Chain Solutions.

3D printing has revolutionized the way businesses operate, allowing them to create products quickly and cost-effectively. This technology has also had a major impact on the supply chain, allowing companies to reduce costs, increase efficiency, and improve customer satisfaction. In this article, we will explore how 3D printing can be used to solve supply chain challenges, from reducing lead times to increasing product customization. We will also discuss the potential benefits and drawbacks of using 3D printing in the supply chain. Finally, we will look at some of the best practices for implementing 3D printing in the supply chain.

How 3D Printing is Revolutionizing Supply Chain Management

The advent of 3D printing has revolutionized the way supply chain management is conducted. 3D printing, also known as additive manufacturing, is a process of creating three-dimensional objects from a digital file. This technology has enabled businesses to reduce costs, increase efficiency, and improve the quality of their products.

The most significant benefit of 3D printing is its ability to reduce costs. By eliminating the need for traditional manufacturing processes, such as injection molding and machining, 3D printing can reduce the cost of production. Additionally, 3D printing eliminates the need for costly inventory management, as products can be printed on demand. This reduces the need for warehousing and storage, resulting in further cost savings.

3D printing also increases efficiency in the supply chain. By eliminating the need for traditional manufacturing processes, 3D printing can reduce lead times and increase production speed. This allows businesses to respond quickly to customer demands and reduce the time it takes to get products to market. Additionally, 3D printing can reduce the need for manual labor, as the process is largely automated.

Finally, 3D printing can improve the quality of products. By eliminating the need for traditional manufacturing processes, 3D printing can produce products with greater accuracy and precision. This can result in higher quality products that are more durable and reliable.

In conclusion, 3D printing has revolutionized the way supply chain management is conducted. By reducing costs, increasing efficiency, and improving the quality of products, 3D printing has enabled businesses to become more competitive and successful. As the technology continues to evolve, it is likely that 3D printing will continue to revolutionize the way supply chain management is conducted.

Exploring the Benefits of 3D Printing for Supply Chain Efficiency

The emergence of 3D printing technology has revolutionized the way businesses operate, and its potential to improve supply chain efficiency is immense. By allowing businesses to produce parts and products on-demand, 3D printing can reduce the need for large inventories, streamline production processes, and reduce lead times. In this article, we will explore the various benefits of 3D printing for supply chain efficiency.

First, 3D printing can reduce the need for large inventories. By allowing businesses to produce parts and products on-demand, 3D printing eliminates the need to store large amounts of inventory. This can significantly reduce overhead costs associated with warehousing and inventory management. Additionally, 3D printing can reduce the risk of stockouts, as businesses can quickly produce parts and products as needed.

Second, 3D printing can streamline production processes. By eliminating the need for tooling and molds, 3D printing can reduce the time and cost associated with producing parts and products. Additionally, 3D printing can reduce the need for manual labor, as the entire production process can be automated. This can significantly reduce labor costs and improve production efficiency.

Third, 3D printing can reduce lead times. By eliminating the need for tooling and molds, 3D printing can significantly reduce the time it takes to produce parts and products. Additionally, 3D printing can reduce the need for manual labor, as the entire production process can be automated. This can significantly reduce lead times and improve customer satisfaction.

Finally, 3D printing can reduce waste. By eliminating the need for tooling and molds, 3D printing can reduce the amount of waste produced during the production process. Additionally, 3D printing can reduce the need for manual labor, as the entire production process can be automated. This can significantly reduce waste and improve resource efficiency.

In conclusion, 3D printing can offer numerous benefits for supply chain efficiency. By reducing the need for large inventories, streamlining production processes, reducing lead times, and reducing waste, 3D printing can significantly improve the efficiency of supply chains. As such, businesses should consider investing in 3D printing technology to improve their supply chain efficiency.

The Impact of 3D Printing on Supply Chain Logistics

The emergence of 3D printing technology has revolutionized the way products are designed, manufactured, and distributed. This technology has had a significant impact on supply chain logistics, allowing companies to reduce costs, increase efficiency, and improve customer service.

3D printing has enabled companies to reduce costs associated with traditional manufacturing processes. By eliminating the need for costly tooling and molds, 3D printing has allowed companies to produce parts and products at a fraction of the cost. Additionally, 3D printing has enabled companies to reduce their inventory costs by producing parts on-demand, eliminating the need to store large amounts of inventory.

3D printing has also increased the efficiency of supply chain logistics. By eliminating the need for long lead times associated with traditional manufacturing processes, 3D printing has allowed companies to produce parts and products quickly and efficiently. Additionally, 3D printing has enabled companies to produce parts and products with complex geometries that would otherwise be impossible to produce using traditional manufacturing processes.

Finally, 3D printing has improved customer service by allowing companies to produce parts and products on-demand. This has enabled companies to respond quickly to customer needs and reduce lead times. Additionally, 3D printing has enabled companies to produce customized parts and products, allowing them to better meet customer needs.

In conclusion, 3D printing has had a significant impact on supply chain logistics. By reducing costs, increasing efficiency, and improving customer service, 3D printing has enabled companies to become more competitive in the global marketplace.

How 3D Printing is Reducing Supply Chain Costs

In recent years, 3D printing has become an increasingly popular technology for businesses looking to reduce supply chain costs. By utilizing 3D printing, businesses can reduce the cost of production, reduce the time it takes to produce goods, and reduce the amount of waste generated during the production process.

3D printing is a process of creating three-dimensional objects from a digital file. This process is often referred to as additive manufacturing, as it involves adding material layer by layer to create the desired object. 3D printing is used in a variety of industries, including automotive, aerospace, medical, and consumer products.

One of the primary benefits of 3D printing is its ability to reduce the cost of production. By eliminating the need for traditional manufacturing processes, such as injection molding and machining, 3D printing can reduce the cost of production significantly. Additionally, 3D printing can reduce the cost of materials, as it requires less material than traditional manufacturing processes.

Another benefit of 3D printing is its ability to reduce the time it takes to produce goods. By eliminating the need for traditional manufacturing processes, 3D printing can reduce the time it takes to produce goods significantly. Additionally, 3D printing can reduce the time it takes to design and develop products, as it allows for rapid prototyping and testing.

Finally, 3D printing can reduce the amount of waste generated during the production process. By eliminating the need for traditional manufacturing processes, 3D printing can reduce the amount of waste generated significantly. Additionally, 3D printing can reduce the amount of energy used during the production process, as it requires less energy than traditional manufacturing processes.

Overall, 3D printing is an effective way for businesses to reduce supply chain costs. By eliminating the need for traditional manufacturing processes, 3D printing can reduce the cost of production, reduce the time it takes to produce goods, and reduce the amount of waste generated during the production process. As such, 3D printing is an increasingly popular technology for businesses looking to reduce supply chain costs.

The Role of 3D Printing in Automating Supply Chain Processes

The use of 3D printing in automating supply chain processes is becoming increasingly popular in the modern business world. 3D printing, also known as additive manufacturing, is a process of creating three-dimensional objects from a digital file. This technology has revolutionized the way businesses operate, allowing them to produce products faster and more efficiently.

3D printing has the potential to revolutionize the supply chain process by automating many of the steps involved. By using 3D printing, businesses can quickly and easily produce parts and components that are needed for their products. This eliminates the need for manual labor and reduces the amount of time and money spent on production. Additionally, 3D printing can be used to create custom parts and components that are not available in the market. This allows businesses to create products that are tailored to their specific needs.

Furthermore, 3D printing can be used to reduce the amount of waste generated during the production process. By using 3D printing, businesses can create parts and components that are exactly the right size and shape for their products. This eliminates the need for excess material and reduces the amount of waste generated.

Finally, 3D printing can be used to reduce the cost of production. By using 3D printing, businesses can produce parts and components at a fraction of the cost of traditional manufacturing methods. This can help businesses save money and increase their profits.

Overall, 3D printing is a powerful tool that can be used to automate many of the steps involved in the supply chain process. By using 3D printing, businesses can produce parts and components faster and more efficiently, reduce the amount of waste generated, and reduce the cost of production. This technology is revolutionizing the way businesses operate and is sure to have a major impact on the future of the supply chain.

Analyzing the Challenges of Implementing 3D Printing in Supply Chain Management

The implementation of 3D printing in supply chain management presents a number of challenges that must be addressed in order to ensure successful implementation. This article will discuss the various challenges associated with 3D printing in supply chain management and provide strategies for overcoming them.

One of the primary challenges of implementing 3D printing in supply chain management is the cost. 3D printing technology is expensive and requires a significant investment in equipment and materials. Additionally, the cost of training personnel to use the technology can be prohibitive. To address this challenge, organizations should consider investing in 3D printing technology that is cost-effective and easy to use. Additionally, organizations should consider partnering with 3D printing service providers to reduce the cost of training personnel.

Another challenge associated with 3D printing in supply chain management is the lack of standardization. 3D printing technology is still relatively new and there is no standardization across different 3D printing technologies. This can lead to inconsistencies in the quality of the products produced and can cause delays in the supply chain. To address this challenge, organizations should consider investing in 3D printing technology that is compatible with existing supply chain management systems. Additionally, organizations should consider developing standards for 3D printing technology to ensure consistency across different 3D printing technologies.

Finally, another challenge associated with 3D printing in supply chain management is the lack of scalability. 3D printing technology is limited in its ability to produce large quantities of products quickly and efficiently. To address this challenge, organizations should consider investing in 3D printing technology that is capable of producing large quantities of products quickly and efficiently. Additionally, organizations should consider partnering with 3D printing service providers to increase the scalability of their 3D printing operations.

In conclusion, the implementation of 3D printing in supply chain management presents a number of challenges that must be addressed in order to ensure successful implementation. By investing in cost-effective 3D printing technology, developing standards for 3D printing technology, and partnering with 3D printing service providers, organizations can overcome these challenges and ensure successful implementation of 3D printing in their supply chain management systems.

Conclusion

In conclusion, 3D printing has the potential to revolutionize the supply chain industry by providing a more efficient and cost-effective way to produce goods. It can reduce lead times, increase product customization, and reduce inventory costs. 3D printing also has the potential to reduce waste and increase sustainability. With the right implementation, 3D printing can be a powerful tool for supply chain optimization.

Resources

- Emerging Technologies Improve Supply Chain: AI, AR, Blockchain, IoT, RPA, Robots…

- Human Robot Production Process with New 3D Printer Factory.

- Top 5 Manufacturing Innovations of the Last Decade

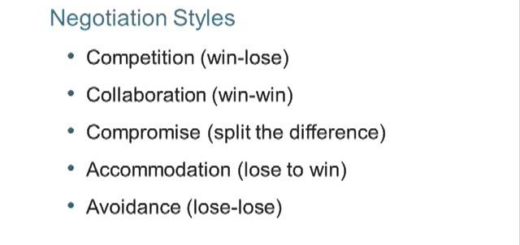

- Supply Chain and Strategy Key Concepts

- Supply Chain Today: Supply Chain Research, News, and Training.

- Unlock the Power of Big Data, Industry 4.0, and IoT to Transform Your Supply Chain!