Guide to the Toyota Supply Chain

Unlock the Power of the Toyota Supply Chain – Get the Guide!

Welcome to the Guide to the Toyota Supply Chain! This guide is designed to provide an overview of the Toyota supply chain and its various components. It will cover topics such as the company’s global supply chain network, its suppliers, its logistics and distribution systems, and its sustainability initiatives. It will also provide an in-depth look at the company’s supply chain management practices and how they have helped Toyota become one of the world’s leading automotive manufacturers. Finally, it will provide an overview of the company’s future plans and how they will continue to shape the industry.

Exploring the Benefits of Toyota’s Supply Chain Management System

Toyota is one of the world’s leading automakers, and its success is largely due to its efficient supply chain management system. This system has enabled Toyota to reduce costs, improve quality, and increase customer satisfaction. In this article, we will explore the benefits of Toyota’s supply chain management system and how it has helped the company become a leader in the automotive industry.

One of the primary benefits of Toyota’s supply chain management system is cost reduction. By streamlining the supply chain process, Toyota has been able to reduce costs associated with production, transportation, and inventory. This has allowed the company to remain competitive in the global market and offer customers competitive prices. Additionally, Toyota’s supply chain management system has enabled the company to reduce waste and increase efficiency. This has resulted in improved quality and customer satisfaction.

Another benefit of Toyota’s supply chain management system is improved customer service. By utilizing a streamlined supply chain process, Toyota has been able to reduce lead times and improve delivery times. This has allowed the company to respond quickly to customer needs and provide better customer service. Additionally, Toyota’s supply chain management system has enabled the company to better manage inventory levels and reduce stockouts. This has resulted in improved customer satisfaction and loyalty.

Finally, Toyota’s supply chain management system has enabled the company to remain competitive in the global market. By utilizing a streamlined supply chain process, Toyota has been able to reduce costs and improve quality. This has allowed the company to remain competitive in the global market and offer customers competitive prices. Additionally, Toyota’s supply chain management system has enabled the company to reduce waste and increase efficiency. This has resulted in improved customer satisfaction and loyalty.

In conclusion, Toyota’s supply chain management system has enabled the company to remain competitive in the global market and offer customers competitive prices. Additionally, the system has enabled the company to reduce costs, improve quality, and increase customer satisfaction. By utilizing a streamlined supply chain process, Toyota has been able to remain a leader in the automotive industry.

How Toyota’s Supply Chain System is Streamlining Logistics

Toyota is a global leader in the automotive industry, and its success is largely due to its efficient supply chain system. The company has developed a comprehensive logistics system that streamlines the process of getting parts and vehicles from the factory to the customer. This system has enabled Toyota to reduce costs, improve customer service, and increase its competitive advantage.

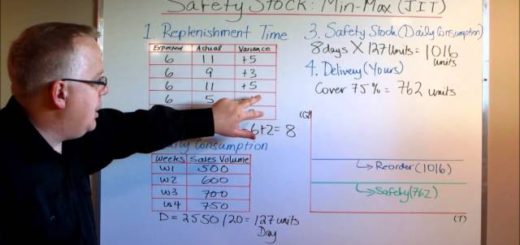

Toyota’s supply chain system is based on the principles of Just-in-Time (JIT) production. This system involves producing only what is needed, when it is needed, and in the quantities needed. This reduces the amount of inventory that needs to be stored and shipped, resulting in lower costs and faster delivery times.

Toyota also uses a variety of technologies to streamline its supply chain. The company has implemented an advanced tracking system that allows it to monitor the progress of parts and vehicles throughout the supply chain. This system allows Toyota to identify potential problems before they become major issues, allowing the company to take corrective action quickly.

In addition, Toyota has invested heavily in automation. Automation has allowed the company to reduce labor costs and increase efficiency. Automated systems can quickly and accurately process orders, track shipments, and manage inventory. This has enabled Toyota to reduce costs and improve customer service.

Finally, Toyota has implemented a number of initiatives to reduce waste and improve sustainability. The company has implemented a number of green initiatives, such as using recycled materials and reducing energy consumption. These initiatives have enabled Toyota to reduce its environmental impact while still maintaining its competitive advantage.

Overall, Toyota’s supply chain system has enabled the company to reduce costs, improve customer service, and increase its competitive advantage. The company’s commitment to streamlining logistics has allowed it to remain a leader in the automotive industry.

Analyzing the Impact of Toyota’s Supply Chain on the Automotive Industry

The automotive industry has been revolutionized by Toyota’s supply chain management. Toyota’s supply chain is a complex system that involves the coordination of multiple suppliers, manufacturers, and distributors to ensure that the right parts are delivered to the right place at the right time. This system has enabled Toyota to become one of the most successful automotive companies in the world.

Toyota’s supply chain has had a significant impact on the automotive industry. By streamlining the production process, Toyota has been able to reduce costs and increase efficiency. This has allowed Toyota to produce vehicles at a lower cost than its competitors, giving it a competitive advantage. Additionally, Toyota’s supply chain has enabled the company to quickly respond to changes in the market, allowing it to stay ahead of the competition.

Toyota’s supply chain has also had a positive impact on the automotive industry as a whole. By streamlining the production process, Toyota has been able to reduce costs for other companies in the industry. This has allowed other companies to produce vehicles at a lower cost, making them more competitive in the market. Additionally, Toyota’s supply chain has enabled other companies to quickly respond to changes in the market, allowing them to stay ahead of the competition.

Overall, Toyota’s supply chain has had a significant impact on the automotive industry. By streamlining the production process, Toyota has been able to reduce costs and increase efficiency, giving it a competitive advantage. Additionally, Toyota’s supply chain has enabled other companies in the industry to reduce costs and quickly respond to changes in the market, allowing them to stay ahead of the competition.

Examining the Role of Technology in Toyota’s Supply Chain

Toyota is one of the world’s leading automotive manufacturers, and its success is largely due to its efficient supply chain. Technology plays a major role in Toyota’s supply chain, allowing the company to streamline processes, reduce costs, and improve customer service.

To begin with, Toyota has implemented a number of technological solutions to improve its supply chain. For example, the company has adopted a sophisticated inventory management system that allows it to track and monitor its inventory in real time. This system allows Toyota to quickly identify any potential problems in its supply chain and take corrective action. Additionally, the company has implemented a number of automated processes, such as automated order processing and automated warehouse management, which have helped to reduce costs and improve efficiency.

Furthermore, Toyota has also adopted a number of technologies to improve customer service. For instance, the company has implemented a customer relationship management (CRM) system that allows it to track customer orders and provide timely updates. Additionally, the company has implemented a number of digital marketing strategies, such as social media campaigns, to reach out to customers and build relationships.

Finally, Toyota has also implemented a number of technologies to improve its sustainability efforts. For example, the company has adopted a number of green technologies, such as solar panels and electric vehicles, to reduce its carbon footprint. Additionally, the company has implemented a number of initiatives to reduce waste and increase recycling.

In conclusion, technology plays a major role in Toyota’s supply chain, allowing the company to streamline processes, reduce costs, and improve customer service. By leveraging technology, Toyota has been able to remain competitive in the automotive industry and ensure its long-term success.

Understanding the Challenges of Toyota’s Supply Chain Management

Toyota is one of the world’s leading automakers, and its success is largely due to its efficient supply chain management. However, managing a global supply chain is a complex and challenging task, and Toyota has faced a number of difficulties in recent years. In this article, we will explore some of the key challenges that Toyota has faced in managing its supply chain.

One of the biggest challenges that Toyota has faced is the need to maintain a high level of quality control. As a global company, Toyota must ensure that its suppliers are producing parts and components that meet its exacting standards. This requires a rigorous quality assurance process, which can be difficult to implement and maintain.

Another challenge that Toyota has faced is the need to keep up with changing customer demands. As customer tastes and preferences evolve, Toyota must be able to quickly adapt its supply chain to meet these changing needs. This requires a high degree of flexibility and agility, which can be difficult to achieve in a large, global supply chain.

Finally, Toyota has also had to contend with the increasing complexity of its supply chain. As the company has grown, its supply chain has become more complex, with more suppliers, more parts, and more components. This complexity can make it difficult to manage the supply chain efficiently, and can lead to delays and inefficiencies.

These are just a few of the challenges that Toyota has faced in managing its supply chain. By understanding these challenges, Toyota can better prepare itself to meet them head-on and ensure that its supply chain remains efficient and effective.

Exploring the Benefits of Toyota’s Global Supply Chain

Toyota is one of the world’s leading automakers, and its success is largely due to its efficient global supply chain. This supply chain is a complex network of suppliers, manufacturers, and distributors that work together to ensure that Toyota’s vehicles are produced and delivered on time and at the highest quality. By leveraging its global supply chain, Toyota has been able to reduce costs, increase efficiency, and improve customer satisfaction.

One of the primary benefits of Toyota’s global supply chain is cost savings. By sourcing parts and components from around the world, Toyota is able to take advantage of lower labor costs and economies of scale. This allows Toyota to produce vehicles at a lower cost than its competitors, which in turn allows them to offer competitive prices to their customers. Additionally, Toyota’s global supply chain allows them to quickly respond to changes in demand, which helps them to avoid costly overproduction.

Toyota’s global supply chain also helps to increase efficiency. By having suppliers and manufacturers located around the world, Toyota is able to reduce the time it takes to get parts and components to its assembly plants. This helps to reduce production times and ensures that vehicles are delivered to customers on time. Additionally, Toyota’s global supply chain allows them to quickly respond to changes in demand, which helps them to avoid costly overproduction.

Finally, Toyota’s global supply chain helps to improve customer satisfaction. By having suppliers and manufacturers located around the world, Toyota is able to quickly respond to customer needs and provide them with the vehicles they want. Additionally, Toyota’s global supply chain allows them to quickly respond to changes in demand, which helps them to avoid costly overproduction. This helps to ensure that customers get the vehicles they want when they want them.

In conclusion, Toyota’s global supply chain has been instrumental in its success. By leveraging its global supply chain, Toyota has been able to reduce costs, increase efficiency, and improve customer satisfaction. This has allowed Toyota to remain competitive in the global automotive market and ensure that its customers get the vehicles they want when they want them.

Analyzing the Impact of Toyota’s Supply Chain on the Environment

Toyota is one of the world’s leading automakers, and its supply chain has a significant impact on the environment. In recent years, Toyota has taken steps to reduce its environmental footprint by improving its supply chain operations. This analysis will examine the environmental impact of Toyota’s supply chain and the measures the company has taken to reduce it.

Toyota’s supply chain is a complex network of suppliers, manufacturers, and distributors that span the globe. The company’s operations require the use of natural resources, energy, and transportation, all of which have an environmental impact. For example, the production of vehicles requires the use of raw materials such as steel, aluminum, and plastic, which are extracted from the earth and processed in factories. The transportation of these materials and finished products also has an environmental impact, as it requires the burning of fossil fuels.

In recent years, Toyota has taken steps to reduce the environmental impact of its supply chain. The company has implemented a number of initiatives to reduce energy consumption and emissions, such as using more efficient engines and improving the efficiency of its manufacturing processes. Toyota has also invested in renewable energy sources such as solar and wind power, and has implemented a number of recycling initiatives.

In addition, Toyota has implemented a number of initiatives to reduce waste and improve the sustainability of its supply chain. The company has implemented a number of initiatives to reduce packaging waste, such as using recycled materials and reducing the amount of packaging used. Toyota has also implemented a number of initiatives to reduce water consumption, such as using water-efficient manufacturing processes and investing in water-saving technologies.

Overall, Toyota’s supply chain has a significant impact on the environment, but the company has taken steps to reduce its environmental footprint. By investing in renewable energy sources, reducing waste, and improving the efficiency of its operations, Toyota is making strides towards a more sustainable future.

Exploring the Role of Quality Control in Toyota’s Supply Chain

The success of Toyota’s supply chain is largely attributed to its commitment to quality control. Quality control is a critical component of Toyota’s supply chain management, as it ensures that the company’s products meet the highest standards of quality and safety. Quality control is a process that involves the identification, prevention, and elimination of defects in the production process. It is a continuous process that involves the use of various methods and techniques to ensure that the products meet the desired quality standards.

Toyota has implemented a comprehensive quality control system that is designed to ensure that all of its products meet the highest standards of quality and safety. This system includes a variety of methods and techniques, such as statistical process control, process capability analysis, and design of experiments. These methods and techniques are used to identify and eliminate defects in the production process.

In addition to these methods and techniques, Toyota also uses a variety of tools and technologies to ensure that its products meet the highest standards of quality and safety. These tools and technologies include automated inspection systems, automated testing systems, and automated quality control systems. These tools and technologies are used to detect and eliminate defects in the production process.

Toyota also has a comprehensive system of quality assurance that is designed to ensure that all of its products meet the highest standards of quality and safety. This system includes a variety of methods and techniques, such as quality audits, process control plans, and corrective action plans. These methods and techniques are used to identify and eliminate defects in the production process.

Finally, Toyota has implemented a comprehensive system of quality management that is designed to ensure that all of its products meet the highest standards of quality and safety. This system includes a variety of methods and techniques, such as quality assurance plans, quality control plans, and quality improvement plans. These methods and techniques are used to identify and eliminate defects in the production process.

In conclusion, Toyota’s commitment to quality control is a key factor in its success in the supply chain. Quality control is a critical component of Toyota’s supply chain management, as it ensures that the company’s products meet the highest standards of quality and safety. Toyota has implemented a comprehensive system of quality control that is designed to ensure that all of its products meet the highest standards of quality and safety. This system includes a variety of methods and techniques, such as statistical process control, process capability analysis, and design of experiments. In addition, Toyota also uses a variety of tools and technologies to ensure that its products meet the highest standards of quality and safety. Finally, Toyota has implemented a comprehensive system of quality management that is designed to ensure that all of its products meet the highest standards of quality and safety.

Conclusion

The Toyota Supply Chain is a complex and intricate system that is constantly evolving to meet the needs of the company and its customers. It is a system that is designed to ensure that the company is able to provide the highest quality products and services to its customers. By understanding the different components of the Toyota Supply Chain, companies can better understand how to optimize their own supply chain operations and ensure that they are able to provide the best possible products and services to their customers.

Toyota Production System (TPS)

The Toyota Production System (TPS) is a lean manufacturing system that Toyota developed in the early 1950s. TPS is based on the principles of waste elimination, continuous improvement, and respect for people. It has been widely adopted by other manufacturers around the world.

TPS has changed the auto industry in many ways, including:

- Improved efficiency: TPS has helped automakers to improve efficiency by reducing waste and eliminating unnecessary steps in the manufacturing process. This has led to lower costs and shorter production times.

- Improved quality: TPS has helped automakers to improve quality by building in quality at the source and by detecting and correcting defects early in the manufacturing process. This has led to fewer recalls and warranty claims.

- Increased flexibility: TPS has helped automakers to increase flexibility by making it easier to change production lines to produce different models or variations of the same model. This has helped automakers to respond more quickly to changes in demand.

- Improved safety: TPS has helped automakers to improve safety by reducing the number of accidents and injuries in the workplace. This has been achieved through a focus on ergonomics and by creating a culture of safety awareness.

- Reduced environmental impact: TPS has helped automakers to reduce the environmental impact of their operations by reducing waste and energy consumption. This has been achieved through a focus on recycling and by using more sustainable materials.

TPS is a complex system, but its basic principles are relatively simple. By focusing on waste elimination, continuous improvement, and respect for people, TPS has helped automakers to become more efficient, productive, and sustainable.

Here are some specific examples of how TPS has changed the auto industry:

- The Just-in-Time (JIT) system: JIT is a key element of TPS. It is a system of manufacturing that produces goods only when they are needed, in the quantities that are needed, and in the time that is needed. This helps to reduce waste and improve efficiency.

- Jidoka: Jidoka is another key element of TPS. It is a system of automation with a human touch. It means that machines are designed to stop automatically if they detect a defect. This helps to prevent defective products from being produced.

- Kaizen: Kaizen is a Japanese word that means “continuous improvement.” It is a philosophy of continuous improvement that is central to TPS. It encourages everyone in the organization to identify and eliminate waste and to make improvements in the way work is done.

TPS is a powerful system that has helped automakers to become more efficient, productive, and sustainable. It is a system that is constantly evolving and improving, and it is likely to continue to have a major impact on the auto industry in the years to come.

Toyota and Lean Manufacturing Resources

- Collection of Quotes about the Toyota Production System.

- How Toyota Changed Manufacturing – Lean Thinking.

- Gemba Walk: the Path to Continuous Improvement

- Lean Manufacturing | A pursuit of perfection.

- Lean Manufacturing: The Path to Success with Paul Akers

- SCM Quotes: Take it to the next level.

- Supply Chain Resources by Topic & Supplier

- Supply Chain Today: Supply Chain Research, News, and Training.

- The Kaizen Way: ONE SMALL STEP CAN CHANGE YOUR LIFE

- What is Kaizen in simple language – Continuous Improvement.