HOW PEPSI IS MADE? INSIDE PEPSI FACTORY

HOW PEPSI IS MADE? INSIDE PEPSI FACTORY.

The manufacturing process for Pepsi, like most carbonated soft drinks, involves several key steps:

- Ingredient preparation: The first step in the manufacturing process is the preparation of the ingredients. This includes sourcing and mixing the various components that make up the Pepsi recipe, such as water, high fructose corn syrup, caramel color, phosphoric acid, caffeine, and natural flavors.

- Carbonation: Once the ingredients are prepared, they are carbonated. Carbonation is the process of adding carbon dioxide to the liquid to create the bubbles that are characteristic of soda.

- Filling and packaging: After carbonation, the Pepsi is then filled into cans or bottles, typically at high speeds using advanced packaging machinery. The cans or bottles are then sealed and labeled.

- Quality control: Before being shipped out, the products go through quality control checks for proper carbonation, fill level, and packaging integrity.

- Distribution and storage: The final step in the manufacturing process is the distribution and storage of the finished product. Pepsi is shipped to warehouses and distribution centers, where it is stored until it is sold to retailers and consumers.

It’s worth noting that the manufacturing process and ingredients may vary slightly depending on the specific Pepsi product being produced, and the facility or region. Additionally, PepsiCo has implemented sustainable practices on their production and packaging processes to reduce environmental impact.

Overall, the manufacturing process for Pepsi involves a combination of advanced technology and automated systems, with a focus on quality control and efficiency. The finished product is then distributed and stored for sale to retailers and consumers.

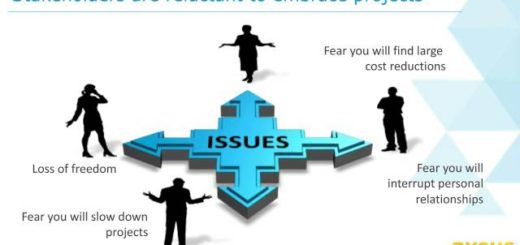

The Pepsi supply chain faces a number of challenges, including:

- Variety: Pepsi produces a wide variety of products, which can make it challenging to manage the supply chain efficiently. Each product has its own unique set of requirements, such as different raw materials, manufacturing processes, and packaging. This can make it difficult to coordinate the flow of goods and materials through the supply chain.

- Globalization: Pepsi operates in a global market, which means that the company has to deal with different cultures, regulations, and transportation costs. This can make it difficult to manage the supply chain effectively. For example, different countries have different import and export regulations, which can add complexity and cost to the supply chain.

- Complexity: The Pepsi supply chain is a complex network of people, organizations, and activities. This can make it difficult to track and control the flow of goods and materials. For example, the company has to track the movement of raw materials from farms to factories, and then the movement of finished products from factories to retailers. This can be a daunting task, especially when there are so many different players involved in the supply chain.

- Risk: The Pepsi supply chain is exposed to a number of risks, such as natural disasters, political instability, and cyberattacks. These risks can disrupt the supply chain and lead to shortages or delays. For example, a natural disaster like a hurricane or flood can damage factories or transportation infrastructure, which can disrupt the flow of goods and materials.

- Sustainability: Pepsi is committed to making its supply chain more sustainable. This means reducing the environmental impact of the supply chain, such as greenhouse gas emissions and water usage. However, this can be a challenge, as it requires changes to the way the supply chain operates. For example, the company may need to use more sustainable packaging or transportation methods.

Pepsi is working to address these challenges by investing in technology, improving collaboration with its suppliers, and developing contingency plans. The company is also committed to making its supply chain more sustainable.

Manufacturing and Supply Chain Information

- Amazing Coca Cola manufacturing line – Inside the soft drink factory.

- ASRS system installed at Pepsi Bottling Company.

- Blogs on how things are made: Cars, Coke, Legos, Pizza, Tequila…

- Conversation with PepsiCo CEO Indra Nooyi.

- How Orange Juice Is Made. Supply Chain of orange juice.

- Manufacturing process of glass bottles.

- Need Supplier Management and Procurement Training? Try these resources

- SCM: The Beer Game.

- Supply Chain Today

- Supply Chain Training & Overview

- The Gigantic Grocery Warehouses Built like Living Organisms

- What Retailers Like Amazon Do With Unsold Inventory

CEO Quotes

- “Celebrate your successes. Find some humor in your failures. Don’t take yourself so seriously. Loosen up, and everybody around you will loosen up. Have fun. Show enthusiasm – always.” ~Sam Walton, Walmart founder.

- “I pick up the details that drive the organization insane. But sweating the details is more important than anything else” ~Indra Nooyi, Pepsi CEO.

- “Supply chains cannot tolerate even 24 hours of disruption. So if you lose your place in the supply chain because of wild behavior you could lose a lot. It would be like pouring cement down one of your oil wells.” ~Thomas Friedman.

- “The smartest people are constantly revising their understanding, reconsidering a problem they thought they’d already solved. They’re open to new points of view, new information, new ideas, contradictions, and challenges to their own way of thinking.” ~Jeff Bezos, Amazon CEO.

- “Retail is a customer business. You’re trying to take care of the customer—solve something for the customer. And there’s no way to learn that in the classroom or in the corner office, or away from the customer. You’ve got to be in front of the customer.” ~Erik Nordstrom.

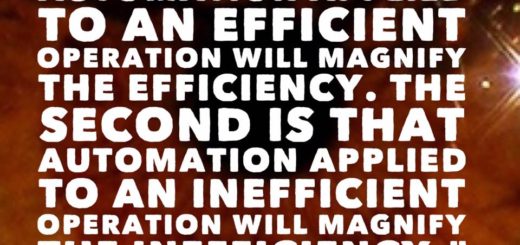

- “Supply Chain automation using emerging technologies such as IoT and artificial intelligence will drive efficiency like we have never seen before.” ~Dave Waters.

- “You walk into a retail store, whatever it is, and if there’s a sense of entertainment and excitement and electricity, you wanna be there.” ~Howard Schultz, CEO Starbucks.