Your Guide to Supply Chain Management.

Introduction

Welcome to Your Guide to Supply Chain Management! This guide is designed to provide you with an overview of the fundamentals of supply chain management and how it can help your business succeed. We will cover topics such as the importance of supply chain management, the different components of a supply chain, and how to effectively manage your supply chain. We will also discuss the challenges and opportunities associated with supply chain management and how to use technology to improve your supply chain operations. By the end of this guide, you will have a better understanding of how to effectively manage your supply chain and how to use technology to your advantage.

The Future of Supply Chain Management and What it Means for Businesses

The future of supply chain management is an exciting prospect for businesses. With the advent of new technologies, businesses are now able to streamline their supply chain processes and increase efficiency. This means that businesses can reduce costs, increase customer satisfaction, and improve their bottom line.

One of the most important aspects of the future of supply chain management is the use of artificial intelligence (AI). AI can be used to automate many of the processes involved in supply chain management, such as inventory management, order fulfillment, and logistics. AI can also be used to analyze data and provide insights into customer behavior and trends. This can help businesses make better decisions and optimize their supply chain operations.

Another important aspect of the future of supply chain management is the use of blockchain technology. Blockchain technology can be used to securely store and transfer data, which can help businesses reduce costs and increase transparency. Blockchain technology can also be used to create smart contracts, which can automate the execution of certain tasks and reduce the need for manual labor.

Finally, the use of the Internet of Things (IoT) is becoming increasingly important in the future of supply chain management. IoT devices can be used to track and monitor the movement of goods, as well as provide real-time data on the status of shipments. This can help businesses reduce costs and improve customer service.

Overall, the future of supply chain management is an exciting prospect for businesses. With the use of new technologies, businesses can reduce costs, increase customer satisfaction, and improve their bottom line. By taking advantage of these new technologies, businesses can ensure that their supply chain operations are as efficient and effective as possible.

The Benefits of Automation in Supply Chain Management

Automation in supply chain management is becoming increasingly important as businesses strive to remain competitive in a global market. Automation can help streamline processes, reduce costs, and improve customer service. Here are some of the key benefits of automation in supply chain management.

1. Increased Efficiency: Automation can help streamline processes and reduce manual labor, resulting in increased efficiency. Automation can also help reduce errors and improve accuracy, resulting in fewer delays and improved customer service.

2. Cost Savings: Automation can help reduce costs associated with manual labor, such as wages, benefits, and training. Automation can also help reduce costs associated with inventory management, such as storage and transportation.

3. Improved Visibility: Automation can help improve visibility into the supply chain, allowing businesses to better track and manage inventory levels. This can help businesses better anticipate customer demand and adjust their supply chain accordingly.

4. Improved Customer Service: Automation can help improve customer service by reducing delays and improving accuracy. Automation can also help businesses better anticipate customer demand and adjust their supply chain accordingly.

Overall, automation in supply chain management can help businesses remain competitive in a global market. Automation can help streamline processes, reduce costs, and improve customer service. By taking advantage of the benefits of automation, businesses can remain competitive and improve their bottom line.

The Role of Logistics in Supply Chain Management

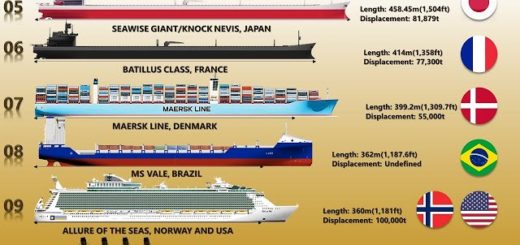

Logistics plays a critical role in supply chain management. Logistics is the process of planning, implementing, and controlling the efficient, cost-effective flow and storage of goods, services, and related information from the point of origin to the point of consumption for the purpose of meeting customer requirements. Logistics is a key component of supply chain management, as it is responsible for the movement of goods and services from one point to another.

Logistics is responsible for the efficient and cost-effective movement of goods and services from the point of origin to the point of consumption. This includes the planning, implementation, and control of the flow of goods and services from the point of origin to the point of consumption. Logistics is also responsible for the storage of goods and services, as well as the tracking and tracing of goods and services.

Logistics is also responsible for the coordination of the various activities involved in the supply chain. This includes the coordination of the various activities involved in the production, distribution, and delivery of goods and services. Logistics is also responsible for the coordination of the various activities involved in the procurement of goods and services.

Logistics is also responsible for the management of inventory. This includes the management of inventory levels, the management of inventory costs, and the management of inventory availability. Logistics is also responsible for the management of the supply chain, which includes the management of the supply chain network, the management of the supply chain processes, and the management of the supply chain performance.

Logistics is also responsible for the management of customer service. This includes the management of customer service levels, the management of customer service costs, and the management of customer service availability. Logistics is also responsible for the management of customer relationships, which includes the management of customer loyalty, the management of customer satisfaction, and the management of customer retention.

Logistics is a critical component of supply chain management, as it is responsible for the efficient and cost-effective movement of goods and services from the point of origin to the point of consumption. Logistics is also responsible for the coordination of the various activities involved in the supply chain, the management of inventory, and the management of customer service. Logistics is essential for the successful management of the supply chain and the achievement of customer satisfaction.

The Benefits of Outsourcing Supply Chain Management

Outsourcing supply chain management (SCM) can be a beneficial strategy for businesses of all sizes. By outsourcing SCM, companies can reduce costs, improve efficiency, and gain access to specialized expertise.

Cost Reduction

Outsourcing SCM can help businesses reduce costs in several ways. By outsourcing, companies can avoid the costs associated with hiring and training in-house staff. Additionally, outsourcing can help businesses reduce overhead costs, such as rent, utilities, and other expenses associated with running a warehouse or distribution center.

Improved Efficiency

Outsourcing SCM can also help businesses improve efficiency. By outsourcing, companies can access the latest technology and processes to streamline their supply chain operations. Additionally, outsourcing can help businesses reduce lead times and improve customer service.

Specialized Expertise

Outsourcing SCM can also provide businesses with access to specialized expertise. By outsourcing, companies can access the knowledge and experience of experienced professionals who can help them optimize their supply chain operations.

Overall, outsourcing supply chain management can be a beneficial strategy for businesses of all sizes. By outsourcing, companies can reduce costs, improve efficiency, and gain access to specialized expertise.

The Challenges of Managing a Global Supply Chain

Managing a global supply chain is a complex and challenging task. It requires a deep understanding of the global market, the ability to anticipate and respond to changes in the market, and the ability to effectively manage resources across multiple countries.

The first challenge of managing a global supply chain is understanding the global market. Companies must be aware of the different economic, political, and cultural factors that can affect their supply chain. They must also be aware of the different regulations and laws that govern the global market. Companies must be able to identify potential risks and opportunities in the global market and develop strategies to capitalize on them.

The second challenge of managing a global supply chain is anticipating and responding to changes in the market. Companies must be able to anticipate changes in the market and develop strategies to respond to them. This includes understanding the different trends in the global market, such as changes in consumer demand, changes in technology, and changes in the competitive landscape. Companies must also be able to quickly adapt their supply chain strategies to respond to these changes.

The third challenge of managing a global supply chain is effectively managing resources across multiple countries. Companies must be able to identify and manage the different resources needed to operate their supply chain, such as labor, materials, and transportation. They must also be able to manage the different costs associated with these resources, such as taxes, tariffs, and currency exchange rates. Companies must also be able to manage the different risks associated with operating in multiple countries, such as political instability, currency fluctuations, and natural disasters.

Managing a global supply chain is a complex and challenging task. Companies must have a deep understanding of the global market, the ability to anticipate and respond to changes in the market, and the ability to effectively manage resources across multiple countries. By understanding these challenges and developing strategies to address them, companies can ensure the success of their global supply chain.

The Impact of Globalization on Supply Chain Management

Globalization has had a profound impact on supply chain management (SCM). In today’s interconnected world, businesses must be able to quickly and efficiently move goods and services across international borders. This has led to an increased focus on SCM, as companies strive to optimize their supply chains to remain competitive in the global marketplace.

Globalization has led to an increased emphasis on the need for efficient and cost-effective supply chains. Companies must now be able to quickly and accurately move goods and services across international borders. This requires a greater focus on the coordination of activities across multiple countries, as well as the ability to manage complex supply chains. Companies must also be able to respond quickly to changes in the global market, such as fluctuations in currency exchange rates or changes in customer demand.

In addition, globalization has led to an increased focus on the need for transparency and traceability in the supply chain. Companies must now be able to track and trace goods and services across multiple countries, as well as ensure that their supply chains are compliant with international regulations. This requires a greater emphasis on the use of technology, such as RFID tags and barcodes, to track and trace goods and services.

Finally, globalization has led to an increased focus on the need for sustainability in the supply chain. Companies must now be able to reduce their environmental impact, while still meeting customer demands. This requires a greater emphasis on the use of green technologies, such as renewable energy sources, as well as the implementation of sustainable practices, such as waste reduction and recycling.

Overall, globalization has had a significant impact on supply chain management. Companies must now be able to quickly and efficiently move goods and services across international borders, while also ensuring that their supply chains are transparent, traceable, and sustainable. By doing so, companies can remain competitive in the global marketplace.

The Role of Technology in Supply Chain Management

Technology has revolutionized the way businesses manage their supply chains. By leveraging technology, companies can reduce costs, improve efficiency, and increase customer satisfaction.

One of the most important ways technology has impacted supply chain management is through the use of automation. Automation allows companies to streamline processes, reduce manual labor, and increase accuracy. Automation can be used to automate order processing, inventory management, and shipping. Automation also allows companies to track their supply chain in real-time, allowing them to quickly identify and address any issues that arise.

Technology has also enabled companies to better manage their supply chain networks. Companies can use technology to connect with suppliers, customers, and other stakeholders in their supply chain. This allows them to quickly identify and address any issues that arise. Additionally, technology can be used to analyze data from the supply chain, allowing companies to identify areas of improvement and make informed decisions.

Technology has also enabled companies to better manage their inventory. Companies can use technology to track inventory levels in real-time, allowing them to quickly identify and address any issues that arise. Additionally, technology can be used to automate the ordering process, allowing companies to quickly and accurately order the right amount of inventory.

Finally, technology has enabled companies to better manage their customer relationships. Companies can use technology to track customer orders, provide customer support, and analyze customer data. This allows companies to better understand their customers and provide them with a better customer experience.

In conclusion, technology has revolutionized the way businesses manage their supply chains. By leveraging technology, companies can reduce costs, improve efficiency, and increase customer satisfaction. Technology has enabled companies to automate processes, better manage their supply chain networks, manage their inventory, and better manage their customer relationships.

How to Develop an Effective Supply Chain Strategy

Developing an effective supply chain strategy is essential for any business that wants to remain competitive in today’s market. A well-crafted supply chain strategy can help a business reduce costs, improve customer service, and increase profits. Here are some tips for developing an effective supply chain strategy.

1. Analyze Your Supply Chain: The first step in developing an effective supply chain strategy is to analyze your current supply chain. Identify areas of inefficiency and areas where improvements can be made. Consider the cost of each step in the supply chain and look for ways to reduce costs.

2. Develop a Vision: Once you have identified areas of improvement, develop a vision for your supply chain. This vision should include goals for cost reduction, customer service, and other areas of improvement.

3. Identify Key Performance Indicators: Once you have developed a vision for your supply chain, identify key performance indicators (KPIs) that will help you measure progress towards your goals. These KPIs should be measurable and should be used to track progress over time.

4. Develop a Plan: Once you have identified KPIs, develop a plan for achieving your goals. This plan should include specific steps for improving efficiency, reducing costs, and improving customer service.

5. Implement the Plan: Once you have developed a plan, it is time to implement it. This may involve making changes to processes, investing in new technology, or hiring new staff.

6. Monitor Progress: Finally, it is important to monitor progress towards your goals. Regularly review your KPIs and make adjustments to your plan as needed.

By following these steps, you can develop an effective supply chain strategy that will help your business remain competitive in today’s market.

The Benefits of Implementing a Supply Chain Management System

The implementation of a supply chain management system can provide a number of benefits to businesses. Supply chain management systems are designed to streamline the flow of goods and services from suppliers to customers, and can help businesses to reduce costs, improve customer service, and increase efficiency.

Cost Reduction: A supply chain management system can help businesses to reduce costs by streamlining the supply chain process. By automating processes such as order processing, inventory management, and shipping, businesses can reduce the amount of time and money spent on manual tasks. Additionally, supply chain management systems can help businesses to identify areas where costs can be reduced, such as by negotiating better deals with suppliers or reducing inventory levels.

Improved Customer Service: A supply chain management system can help businesses to improve customer service by providing real-time visibility into the supply chain process. This visibility can help businesses to identify and address any issues that may arise, such as delays in delivery or incorrect orders. Additionally, supply chain management systems can help businesses to provide customers with accurate and up-to-date information about their orders, such as estimated delivery times.

Increased Efficiency: A supply chain management system can help businesses to increase efficiency by automating processes such as order processing, inventory management, and shipping. This automation can help businesses to reduce the amount of time and money spent on manual tasks, freeing up resources to focus on other areas of the business. Additionally, supply chain management systems can help businesses to identify areas where processes can be improved, such as by reducing lead times or increasing order accuracy.

Overall, the implementation of a supply chain management system can provide a number of benefits to businesses. By streamlining the supply chain process, businesses can reduce costs, improve customer service, and increase efficiency.

What is Supply Chain Management and How Does it Work?

Supply chain management (SCM) is the process of managing the flow of goods and services from the point of origin to the point of consumption. It involves the coordination and integration of all activities within the supply chain, including procurement, production, inventory management, transportation, warehousing, and customer service.

The goal of SCM is to ensure that the right products are delivered to the right place at the right time, while minimizing costs and maximizing customer satisfaction. To achieve this, SCM requires the integration of multiple functions and processes, including planning, sourcing, manufacturing, logistics, and customer service.

The first step in SCM is planning. This involves setting goals and objectives, determining the resources needed to meet those goals, and developing a strategy to achieve them. This includes forecasting demand, setting production schedules, and determining the most cost-effective way to source materials and components.

The next step is sourcing. This involves finding the best suppliers for the materials and components needed to produce the goods or services. This includes evaluating potential suppliers, negotiating contracts, and managing supplier relationships.

The third step is manufacturing. This involves transforming raw materials into finished products. This includes setting up production lines, managing production processes, and ensuring quality control.

The fourth step is logistics. This involves managing the movement of goods from the point of origin to the point of consumption. This includes managing inventory, scheduling transportation, and ensuring timely delivery.

The fifth step is customer service. This involves providing support to customers, such as answering questions, resolving complaints, and providing technical assistance.

By integrating these five steps, SCM enables organizations to optimize their supply chain operations and ensure that the right products are delivered to the right place at the right time, while minimizing costs and maximizing customer satisfaction.

Conclusion

In conclusion, Your Guide to Supply Chain Management is an invaluable resource for anyone looking to gain a better understanding of the complexities of supply chain management. It provides a comprehensive overview of the various components of the supply chain, from procurement and inventory management to logistics and customer service. It also offers practical advice on how to optimize the supply chain for maximum efficiency and cost savings. With its clear and concise explanations, Your Guide to Supply Chain Management is an essential tool for anyone looking to improve their supply chain operations.

Supply Chain Resources

- Apple’s Supply Chain Strategy. Lessons from Steve Jobs | iPhone Logistics.

- Automation Changing Supply Chain

- Coca Cola Supply Chain

- End to End Supply Chain Process

- SCM Resources by Topic & Supplier

- SCM Collaboration Resources on Social Media.

- Supply Chain Today.

- Supply Chain and Strategy Key Concepts

- The Tesla Global Supply Chain!

- What is Supply Chain Management?

Learn by Primary SCM Process

- Plan: What is Supply Chain Planning and Strategy?

- Buy: What is Supplier Management and Procurement?

- Store: What is Distribution, Warehouse and Inventory Management?

- Make: What is Manufacturing?

- Ship: What is Transportation, Logistics and Shipping?

- Return: What is Return and Reverse Logistics?