The process of making Tequila.

The process of Making Tequila. How is your favorite beverage made?

Tequila is a type of liquor made from the blue agave plant, primarily grown in the area surrounding the city of Tequila, 65 km (40 mi) northwest of Guadalajara, and in the highlands (Los Altos) of the central Mexican state of Jalisco. Here is an overview of the process of making tequila:

- Harvesting the agave: The agave plant takes between 7 and 12 years to mature before it is ready to be harvested. The leaves of the plant are trimmed away, leaving the piña, or heart, of the agave plant.

- Cooking the piñas: The piñas are then cooked, usually by steaming them in ovens or autoclaves. This process helps to break down the fibers and release the juices from the plant.

- Milling: The cooked piñas are then crushed to extract the juice, which is called aguamiel (honey water). This is typically done using a machine called a tahona, which consists of a large stone wheel that is turned by a donkey or a motor.

- Fermentation: The aguamiel is then fermented using yeast to convert the sugars into alcohol. This process can take several days to a week.

- Distillation: The fermented liquid is then distilled to increase the alcohol content and produce the final product, which is called tequila.

- Aging: Some tequilas are aged in oak barrels, which can add flavor and complexity to the final product.

Overall, the process of making tequila involves several steps, including harvesting the agave, cooking the piñas, milling, fermentation, distillation, and aging. The end result is a distinctive and popular liquor enjoyed around the world.

How Patrón Makes Its Tequila

Process of Making Tequila

How things are made.

- Coca-Cola – How Coca Cola Is Made. Great video.

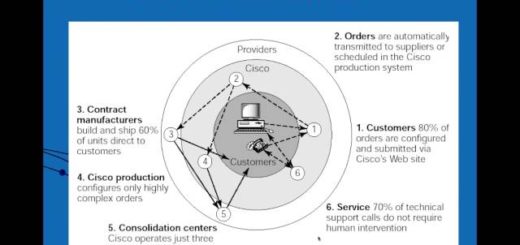

- End To End Supply Chain Management Process.

- Ferrari – Putting together a Ferrari.

- Glass Bottles – Manufacturing process glass bottles.

- Hot Dogs – How hot dogs are made.

- Ketchup – How Tomato Ketchup Is Made.

- Legos – How Legos are made.

- Orange Juice – How Orange Juice is Made.

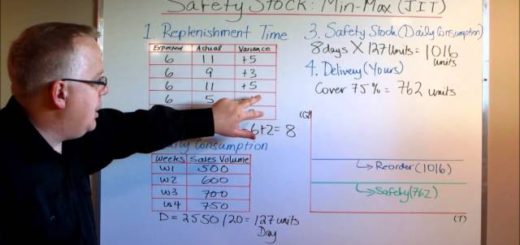

- Supply Chain and Strategy Key Concepts.

- Supply Chain Training & Overview.

- What is Manufacturing?

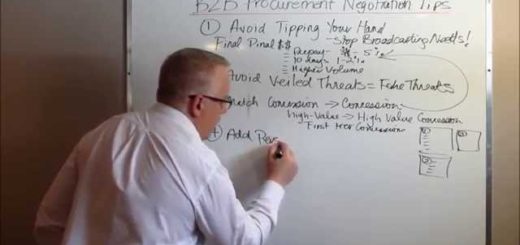

- What is Supplier Management and Procurement?

Manufacturing Quotes

- “If you can’t describe what you are doing as a process, you don’t know what you’re doing.” ~W. Edwards Deming

- “Almost all quality improvement comes via simplification of design, manufacturing, layout, processes, and procedures.” ~Tom Peters

- “An hour saved at the non-bottleneck is a mirage.” ~ Eliyahu M. Goldratt, The Goal

- “Many of our best opportunities were created out of necessity. “ ~ Sam Walton, founder of Walmart

- “For much of Toyota’s history, we have ensured the quality and reliability of our vehicles by placing a device called an andon cord on every production line – and empowering any team member to halt production if there’s an assembly problem. Only when the problem is resolved does the line begin to move again.” ~Akio Toyoda, CEO Toyota Motor Company

- “Out of clutter, find simplicity. From discord, find harmony. In the middle of difficulty lies opportunity.” ~Albert Einstein

- “Supply chains are everywhere. From the biggest company in the world to running your household. We all have supply chain experience even if we don’t know it.” ~ EverythingSupplyChain.com

- “It is impossible to improve any process until it is standardized. If the process is shifting from here to there, then any improvement will just be one more variation that is occasionally used and mostly ignored. One must standardize, and thus stabilize the process, before continuous improvement can be made.” ~Masaaki Imai