The Bullwhip Effect 101. 5 min video, 16k views.

The Bullwhip Effect 101.

The bullwhip effect is a phenomenon that can occur in supply chain management, in which small changes in demand at the retail level can lead to larger and more volatile changes in demand at the wholesale and manufacturing levels. This can result in overproduction, excess inventory, and inefficient use of resources.

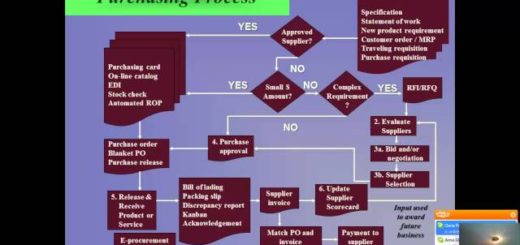

There are several factors that can contribute to the bullwhip effect, including:

- Order batching: When orders are placed in large batches rather than on a regular basis, it can lead to fluctuations in demand. For example, if a retailer places a large order for a product every six months, rather than placing smaller orders on a weekly or monthly basis, this can result in increased demand at the wholesale and manufacturing levels.

- Forecast errors: If demand is difficult to predict, it can lead to errors in forecasting, which can result in overproduction or underproduction.

- Price fluctuations: Changes in price can affect demand and can lead to fluctuations in the supply chain.

- Information delays: If there are delays in the flow of information between different levels of the supply chain, it can lead to inaccurate demand forecasts and production decisions.

To mitigate the bullwhip effect, it is important for companies to implement strategies to improve the flow of information and demand forecasting, such as using just-in-time production methods, implementing a pull-based production system, and using advanced analytics to improve demand prediction.

Supply Chain Training.

- Amazon Warehouse – behind the scenes.

- Bullwhip Effect: How Sudden Demand Increases Affect Supply Chains.

- Converse Automated Distribution Center.

- Coronavirus Update: Supply Chain, Food Shortages, Stock Market.

- Distribution Centers & Supply Chain Management Explained.

- FedEx and UPS Documentary.

- Horizontal Carousel Warehouse Automated Storage and Retrieval System – ASRS.

- Overview of Logistics and Supply Chain Management.

- SCM: The Beer Game. 45 min video. 75K views

- Supply Chain Master: Professor Hau Lee on the bullwhip effect.

- Supply Chain Technology Trends 2020.

- The Beer Game – Supply Chain Management.

“A good rule in organizational analysis is that no meeting of the minds is really reached until we talk of specific actions or decisions. We can talk of who is responsible for budgets, or inventory, or quality, but little is settled. It is only when we get down to the action words-measure, compute, prepare, check, endorse, recommend, approve-that we can make clear who is to do what.” ~Joseph M. Juran

“Labor accounts for 75% of the cost of transporting shipments by truck, so adopters can begin to realize those savings. Beyond that, while truckers are prohibited from driving more than 11 hours per day without taking an eight-hour break, a driverless truck can drive for the entire day.” ~Ryan Petersen

“Celebrate your successes. Find some humor in your failures. Don’t take yourself so seriously. Loosen up, and everybody around you will loosen up. Have fun. Show enthusiasm – always.” ~Sam Walton.

“There are two ways to extend a business. Take inventory of what you’re good at and extend out from your skills. Or determine what your customers need and work backward, even if it requires learning new skills. Kindle is an example of working backward.” ~Jeff Bezos